Certified in Production and Inventory Management - Master Planning of Resources v6.0

Question 1

Capacity planning occurs at what stage of the Sales and Operations Planning (S&OP) process?

- A. Demand planning phase

- B. Supply planning phase

- C. Pre- SOP meeting

- D. Executive SOP meeting

Answer : B

Question 2

A forecasting method that responds slowly to changes in demand would be most appropriate when the historical demand pattern shows a major:

- A. seasonal component.

- B. random component.

- C. trend component.

- D. cyclical component.

Answer : B

Question 3

The resource profile approach to rough-cut capacity planning is desirable in the manufacture of parts with lengthy lead times because the approach:

- A. uses detailed data about time standards for each product at the key resources.

- B. assumes that all components are built in the same period as the end item.

- C. considers the historical portion of the total plant time required.

- D. time phases labor requirements.

Answer : D

Question 4

In a make-to-stock environment, which of the following factors is a key determinant of inventory levels necessary to support customer demand?

- A. Capable-to-promise

- B. Available-to-promise

- C. Service costs

- D. Service level

Answer : D

Question 5

In the master scheduling process, customer orders are the only source of demand in periods:

- A. within the item lead time.

- B. before the demand time fence.

- C. between the demand and planning time fences.

- D. beyond the planning time fence.

Answer : B

Question 6

A Canadian-based company has a long-term contract with a US-based supplier. The

Canadian company has been experiencing short shipments and variations of the supply lead time with the US supplier for a few months. Which of the following is the most appropriate action for the master production scheduler in this situation?

- A. Ask the purchasing manager to work with the supplier to improve their shipping quantity accuracy and lead time stability.

- B. Ask the purchasing manager to terminate the contract with this supplier, and look for a better supplier.

- C. Apply safety stock and safety lead time while planning the master production schedule.

- D. Apply safety lead time according to the target service level while planning the master production schedule.

Answer : D

Question 7

Which of the following issues is most likely to lead to the use of a short-term, rather than long-term, forecasting process?

- A. How to respond to a competitor's test marketing of a new product

- B. How to configure the supply chain to support a new market segment

- C. Whether to outsource a capital-intensive subassembly process

- D. Whether to take a price-leadership or a product-differentiation posture

Answer : A

Question 8

A company wanting to maintain a high level of customer service at the lowest inventory carrying cost should place safety stock in:

- A. central and field warehouses.

- B. field warehouses.

- C. a central warehouse.

- D. customer's facilities.

Answer : C

Question 9

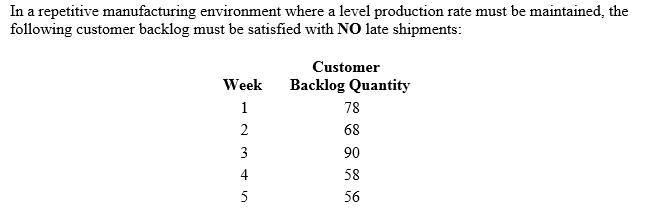

The question below is based on the following information:

Which of the following weekly production rates best supports these criteria?

- A. 70

- B. 78

- C. 80

- D. 90

Answer : C

Question 10

Production is being planned to emphasize the utilization of a critical and very expensive piece of capital equipment. Which of the following production planning strategies should be used?

- A. Chase

- B. Level

- C. Cost-based

- D. Combination

Answer : B

Question 11

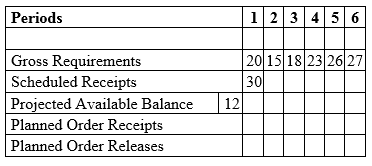

The question below is based on the following distribution requirements plan:

Lead time is 1 week, lot size is 30, and safety stock is 0. Planned order releases would occur in which of the following sequences?

- A. Weeks 3, 4, 6

- B. Weeks 2, 3, 5

- C. Weeks 2, 3, 4

- D. Weeks 3, 4, 5

Answer : B

Question 12

Translation of a master production schedule directly into key resources results in a:

- A. production schedule.

- B. final assembly schedule.

- C. rough-cut capacity plan.

- D. bill of labor.

Answer : C

Question 13

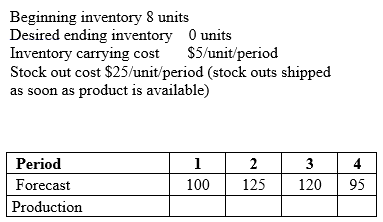

The question below is based on the following information:

A company has chosen to execute a level production plan. What is the production rate per period?

- A. 108

- B. 110

- C. 112

- D. 125

Answer : A

Question 14

Which of the following goals is the primary outcome of distribution requirements planning?

- A. Accurately feed the gross requirements into the master production schedule

- B. Decouple the distribution plan from the production plan

- C. Deliver products in the quantities requested by the customer

- D. Maintain an appropriate inventory level at all locations

Answer : D

Question 15

The greatest risk of aggregating product families at too high of a level for sales and operations planning is that:

- A. it will be more difficult to reconcile the sales plans with the business plan.

- B. imbalances between the demand plan and resources may not be visible.

- C. the resource planning process will be more complicated.

- D. the sales forecasts will not be as accurate for the larger product families.

Answer : B