Execution and Control of Operations v7.0

Question 1

Statistical process control is a technique primarily used to:

- A. implement mistake-proofing techniques.

- B. identify special-cause variation.

- C. reduce preventive maintenance.

- D. reduce the number of inspection steps.

Answer : B

Question 2

Management most likely would use which of the following tools to improve communication and feedback on daily progress to its employees?

- A. Newsletters distributed to every worker

- B. Wall charts showing standards and actuals

- C. Key performance indicators

- D. The company's website

Answer : B

Question 3

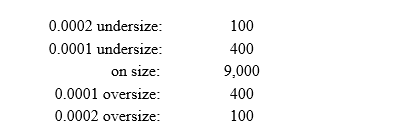

A supplier of roller bearings makes lots of 10,000 and sorts them automatically according to size. In a typical lot of 10,000, the sizes break into the following categories:

The product requires rollers on target or, at most, 0.0001 oversize. Experience indicates that 100% must be reinspected before use because the machine inspection lets a few defective units slip through. The supplier should be encouraged to take which of the following actions?

- A. Learn what factors cause variability.

- B. Tighten the inspection criteria.

- C. Seek deviations from Quality Control.

- D. Doubly inspect the rollers

Answer : A

Question 4

Operation-to-operation quantity reporting is most important to which of the following production environments?

- A. Job-lot production

- B. Process production

- C. Repetitive manufacturing

- D. Continuous manufacturing

Answer : A

Question 5

Which of the following concepts is a reason to create a visual factory?

- A. They are more successful because visual systems are more robust.

- B. They are inexpensive to implement.

- C. They are more successful because they display well for customer visits.

- D. They are successful because they are self-explaining and self-improving.

Answer : D

Question 6

Which of the following project characteristics would suggest using the PERT technique, rather than the critical path method?

- A. Estimates of individual task times are probabilistic.

- B. Project tasks are backward scheduled.

- C. Due dates are needed to identify critical tasks.

- D. Project management can determine the critical path.

Answer : A

Question 7

A work center has one machine that is operated for one shift per day. The shop runs an 8- hour shift 5 days per week. Machine utilization has been 60% with efficiency at 80%. A routing through this work center has a standard run time of .10 hours per piece. Job number 1234 is for 200 pieces. If the utilization is improved to 80%, the difference in calculated lead time for the job is how many days?

- A. 1.0

- B. 1.3

- C. 2.1

- D. 2.7

Answer : B

Question 8

The implementation of a program designed to reduce changeover times will result in a temporary capacity shortage. This shortage will be handled by using some older equipment and by subcontracting some work. Which of the following methods should the company use to control capacity during this period?

- A. Kanban

- B. Demand management

- C. Flow control

- D. Input/output control

Answer : D

Question 9

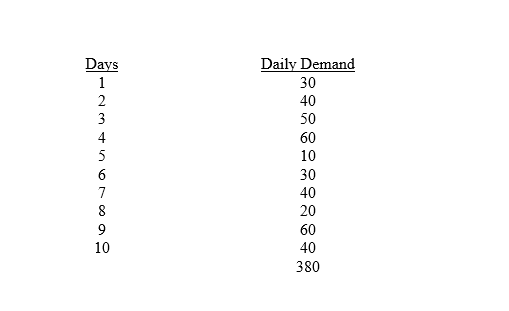

Based on the data provided, assume that time available per day is 840 minutes. What is the takt time per unit of demand?

- A. 84.0 minutes

- B. 22.1 minutes

- C. 2.21 minutes

- D. 8.4 minutes

Answer : B

Question 10

Based on the theory of constraints (TOC) scheduling approach, smaller lots created as a result of splitting order quantities are considered to be:

- A. period order quantities.

- B. bottleneck batches.

- C. transfer batches.

- D. campaign orders.

Answer : C

Question 11

In a work center that requires a large number of tooling changes, the best way to increase productivity is to:

- A. manage work center queue.

- B. optimize run time.

- C. reduce setup time.

- D. implement theory of constraints.

Answer : C

Question 12

Which item is a role of the six sigma champion?

- A. Acting as an internal six sigma consultant

- B. Removing barriers the teams eccounter

- C. Providing technical support and mentoring

- D. Identifying possible causes of the problem

Answer : B

Question 13

To successfully implement a multiple-site pickup of parts from different suppliers, it is necessary that:

- A. customers use contract carriers.

- B. suppliers have their products ready at specified times.

- C. suppliers be located close to their customers' sites.

- D. electronic data interchange be used.

Answer : B

Question 14

Proper workplace organization calls for which of the following actions?

- A. Increasing supervisor oversight

- B. Returning frequently used items to a nearby, fixed location

- C. Increasing the use of kanbans

- D. Placing all tools in a centrally located tool crib

Answer : B

Question 15

A production manager uses a hoshin plan to communicate:

- A. financial status.

- B. operational issues.

- C. new ideas.

- D. strategy.

Answer : D